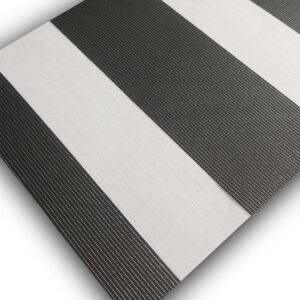

Description

The Day and Night Roller blind, also known as a Vision blind, is a smart design that gives you style and light control within the one blind. The blind has two alternating parallels of opaque and translucent fabric. By simply adjusting the position of the blind, one can choose to align the back and front opaque and translucent layers in such a way to create a unique light filtering effect suitable for any contemporary living space. Fabric material is 100% polyester. Made of a strong, aluminium roller tube that is increased in diameter for wider blinds to ensure the blind does not bend. Supplied with an easy-fit bracket system with a spring-loaded pin end and metal brackets. Comes complete with all brackets. The brackets can be top or face fixed. Supplied with a child safety clip for peace of mind.